CBR

Safer, higher, smarter barrel storage

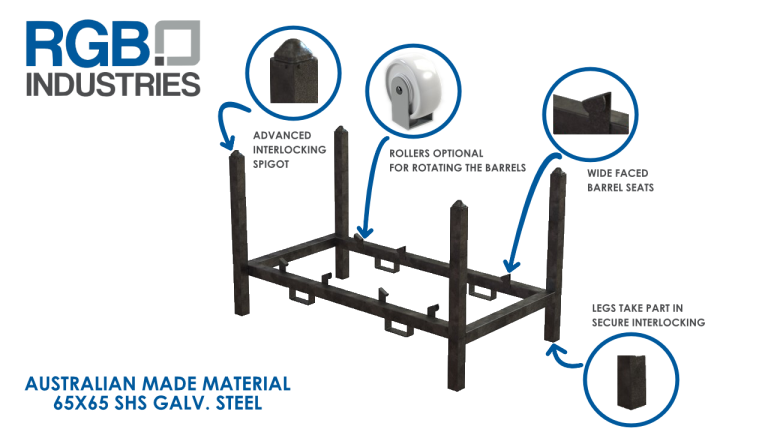

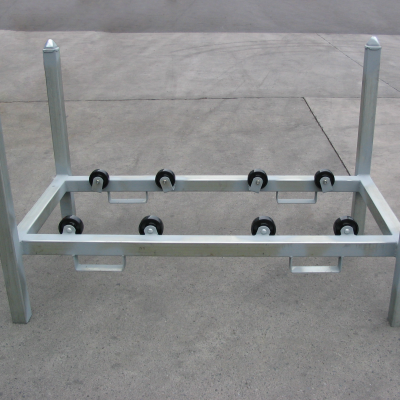

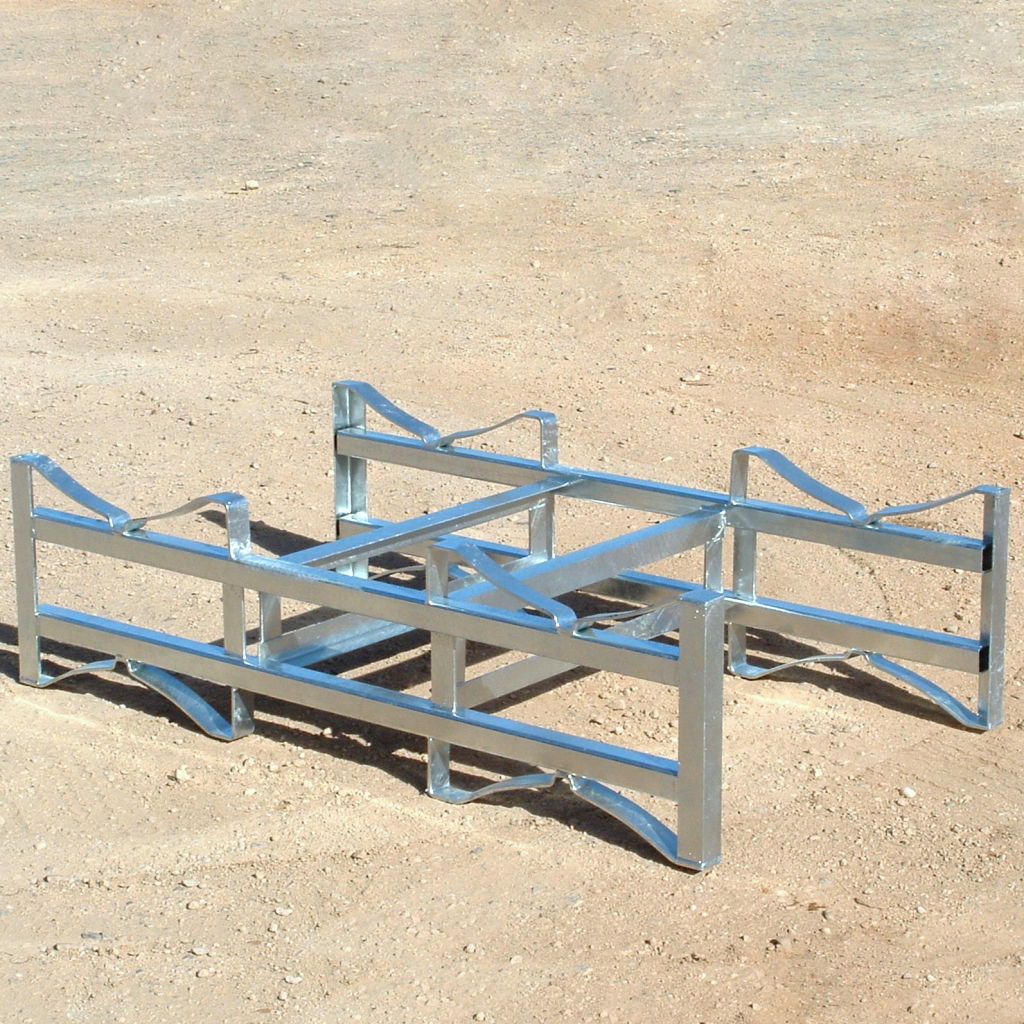

The RGB CBR is our exclusive, innovative barrel-storage system engineered for safety, manageability, and space utilisation. Each rack holds two barrels and can stack six-high as standard or eight-high with High-Stack upgrade. In sheds with sufficient roof height, storage density can increase by up to 40%. Unlike conventional systems, the barrel never carries the load—each rack supports the weight of the racks above it.

Why winemakers choose CBR

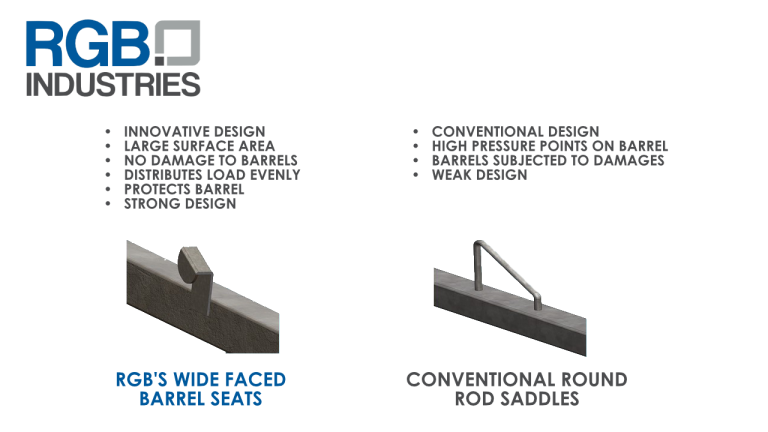

No load on the barrel – barrels are supported within the frame, not by each other, reducing damage risk and improving OH&S.

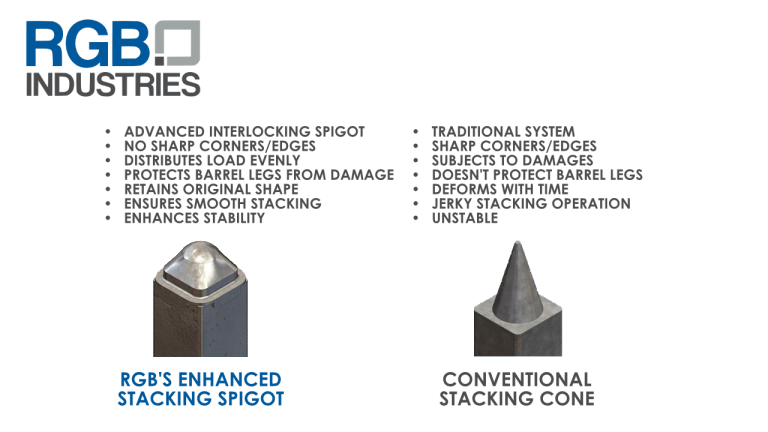

Straight, stable stacks – proprietary interlocking nesting plugs on all posts lock stacks into alignment, eliminating time-consuming barrel-matching and finicky positioning. The unique interlocking mechanism significantly reduces the chances of any accidents that might occur due to misalignment or instability of stacks, further ensuring safety for the personnel managing the barrels.

Proven productivity – barrel shed logistics efficiencies of up to 35% have been achieved with the CBR system.

Seismic confidence – particularly effective in earthquake conditions; widely adopted in seismically active regions including Canada, the USA, and New Zealand.

Engineer-approved heights – High-Stack CBR stacks (8-high) are engineer approved and earthquake rated for seismic activity.

Built for durability

All-galvanised construction with welds treated in cold-galvanising paint as standard.

Hot-dip galvanised finish available for maximum corrosion protection.

- All structural steel used in our manufacture complies with recognised Australian standards — including AS/NZS 1163:2016 for cold-formed hollow sections and AS/NZS 1554.1:2014 for welding quality. Finished products destined for outdoor or exposed installations are hot-dip galvanised in accordance with AS/NZS 4680 to ensure long-term corrosion resistance

Smarter handling & cellar operations

The innovative design of the CBR ensures that barrels are easily accessible, facilitating quick inventory checks and minimizing the time spent on logistics. Enhanced access not only streamlines operations but also allows staff to focus on quality assurance during the winemaking process, ensuring that each barrel is monitored and managed effectively.

To complement the system, RGB has developed forklift barrel-lifting attachments to eliminate manual handling concerns. You can also add the optional roller kit to rotate barrels in-rack to any position—ideal for agitation, cleaning, and precise positioning throughout the winemaking process.

Sizes & custom options

CBR racks are available for a wide range of barrel sizes, including barrique, hogshead, and puncheon. Working with non-standard barrels? We’ll custom-build to suit.

Protected design

The CBR system is protected by granted patent and registered design.